At Affan Interlinings Ltd., quality, precision, and innovation are at the core of our manufacturing process. Every stage is carefully designed to ensure our interlinings meet the highest global standards while catering to the diverse needs of the apparel industry.

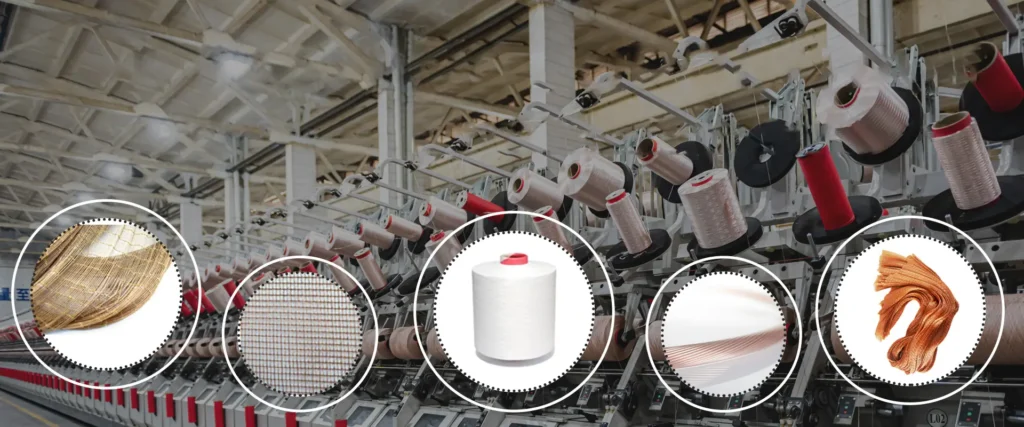

We source only premium fibers and fabrics from trusted suppliers. Each material is carefully inspected for strength, texture, and consistency to guarantee durability and superior performance in finished garments.

Our skilled production team utilizes advanced weaving, knitting, and non-woven techniques to create over 600 varieties of interlinings. From fusible to non-fusible, cotton to synthetic, and specialty eco-friendly products, our methods are tailored to meet specific garment requirements.

Interlinings are treated with precision for optimal fusibility, softness, and hand feel. Whether for formal shirts, jackets, suits, or knitwear, we ensure the perfect balance between structure and flexibility.

Every batch undergoes extensive quality checks for strength, shrinkage, adhesion, dimensional stability, and compatibility. Our adherence to GRS, ISO, OEKO-TEX, and TQP standards ensures products consistently meet international expectations.

Finished interlinings are carefully packed using methods that preserve quality and prevent damage during transportation. We maintain reliable delivery schedules to serve clients worldwide efficiently.

Affan’s production process is supported by state-of-the-art machinery, experienced technicians, and a strong culture of continuous improvement. We invest in R&D and green initiatives to ensure our interlinings remain technologically advanced and environmentally responsible.

Founded in 2002 at the BSCIC Industrial Estate, Sagorica Road, Chattogram, Affan Interlinings Ltd. has grown into one of the leading woven and non-woven interlining manufacturers in Bangladesh.

BSCIC I/A,Chittagong, BD

+880-29-850-852

info@affaninterlinings.com

Satday - Thuday 09 AM - 5 PM